Check valves are designed to pass flow in one direction with minimum resistance and to prevent reverse or back flow with minimal leakage. The principal types of check valves used are the tee-pattern lift check, the swing check, the tilting-disc check, the Wye-pattern lift check, and the ball check, illustrated in Figs. A to E, respectively.

Construction of a Check Valve

A basic check valve consists of a valve body, bonnet or cover, and a disc which is attached to a hinge and swings away from the valve seat to allow fluid to flow in the forward direction, as in a swing- or tilting-disc check valve, and returns to valve seat when upstream flow is stopped. Thus, reverse flow is prevented. In folding disc check valves, the disc consists of two halves attached in the middle. The two halves fold backward when upstream flow is initiated. Activated by a spring, the two halves quickly close the flow path when upstream flow ceases. In the case of lift-check valves, the disc is in the form of a piston which is moved out of the flow path by upstream flow and returns to the valve seat by gravity to stop back flow. Ball-check valves have a disc in the form of a ball.

Check valves are available in sizes from NPS ¹⁄₄ (DN 6) through NPS 72 (DN 1800). Other sizes may be made available to meet specific size requirements. Depending upon the design requirements of a piping system, a check valve may have butt welding, socket welding, threaded, or flanged ends.

Advantages of Check Valves

They are self-actuated and require no external means to actuate the valve either to open or close. They are fast acting.

Disadvantages of Check Valves

The following are some of the disadvantages that are attributed to check valves:

1. Since all moving parts are enclosed, it is difficult to determine whether the valve is open or closed. Furthermore, the condition of internal parts cannot be assessed.

2. Each type of check valve has limitations on its installation configurations.

3. Valve disc can stick in open position.

Types of Check Valves

There are several types of check valves having varying body configurations. The following are some commonly used types of check valves:

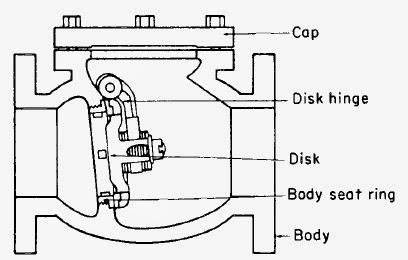

Swing Check Valve

|

| Fig. A: Swing check valve |

In swing check valves, the disc is unguided when it moves to fully open position or to fully closed position. Many different disc and seat designs are available to satisfy requirements of varying applications. Soft-seated–swing check valves provide improved leak tightness compared to metal-to metal seating surfaces. Combination seats consisting of a metal seat ring with resilient insert also offer better leak tight characteristics. The seating angle, the angle between the seat and the vertical plane, may vary from 0 to 45 degrees. Vertical seats have a 0 angle. Larger seat angles reduce the disc travel, resulting in quick closing, thus minimizing the possibility of water hammer. Usually the seat angles are in the range of 5 to 7 degrees.

Lift Check Valve

Lift check valves are particularly adapted for high-pressure service where velocity of flow is high. In lift check valves, the piston disc is accurately guided by long contact and a close sliding fit with the perfectly centered dash pot. The walls of the piston and dash pot are of approximately equal thickness. Large steam jackets are located outside of the dash pot and inside the piston to eliminate sticking because of differential expansion. The seat ring is of a barrel-type design of heavy uniform cross-section. It is normally screwed in and seal welded. The flow opening is full port size. Refer to Figs. A and G.

|

| Fig. B: Lift check valve |

The seat design of a lift-check valve is similar to a globe valve. The disc is usually in the form of a piston or a ball. The ball-lift check valves are used in highly viscous fluid service. These valves have superior leak tight characteristics to those of swing check valves.

|

| Fig. G: Wye-pattern lift check valve |

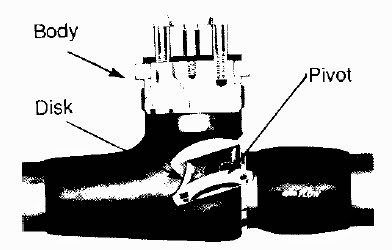

Tilting Disc Check Valve

|

| Fig. C: Tilting-disc check valve |

The tilting-disc check valve is designed to overcome some of the weaknesses inherent in conventional swing check valves. A combination of design features enables the valve to open fully and remain steady at lower flow velocities and to close quickly upon cessation of forward flow. The dome-shaped disc floats in the flow with fluid on both bottom and top of its surfaces, thus it has minimum dash pot effect. It performs well in pulsating, turbulent, and high-velocity flows. These attributes prolong the valve’s lift and reduce flow-induced dynamic loads on the piping system. Refer to Fig. C.

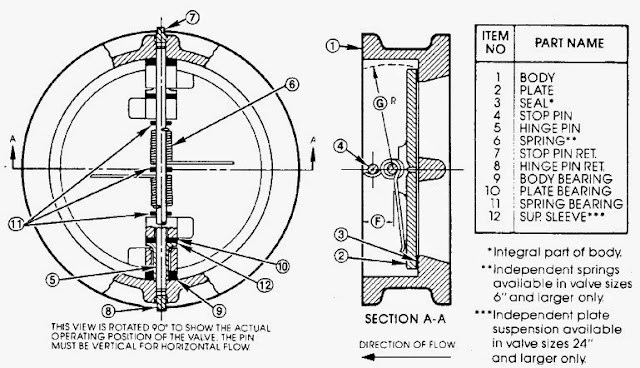

Folding Disc Check Valves

|

| Fig. D: Folding-disc check valve |

This valve is also referred to as double-disc or split disc check valve. Refer to Fig. D. It is manufactured in wafer-body pattern and is available with soft or hard seats. It is very popular in low-pressure liquid and gaseous services. Its lightweight compact construction makes it a preferable check valve when space and convenience are important.

Vertical or In-Line Check Valve

These valves are available in two configurations: in-line ball check and fully guided disc with soft or hard seats. In-line ball check valves can be used in both vertical and horizontal lines. The fully guided disc inline check valves must be provided with a spring-assist closure when used in horizontal lines. In vertical lines, the guided disc in-line check valves may or may not be provided with spring-assist closure. The spring-assist closure not only assists in closing the valve quickly, it minimizes the possibility of water hammer by preventing

flow reversal.

flow reversal.

They can be used in applications having pulsating flows, such as in a discharge line of a reciprocating compressor. Because they are compact in size, they are ideal for application in tight spaces.

Stop Check Valve

A stop check valve can either be used as a unidirectional check valve or as an isolation (stop) valve like a gate or globe valve. During normal operation of a system, these valves are used as a regular check valve; however, when needed, these valves can be closed with the help of a screw-down stem which is not fastened to the valve disc. The stem, when fully screwed down, holds the free-floating disc against the valve seat, just as in a gate or a globe valve. These valves are available in tee-pattern, wye-pattern, angle-pattern, and inclined pattern.

|

| Fig. E: Swing-disc stop check |

|

| Fig. F: Wye-pattern stop check |

The swing-and-piston lift-disc design check valves are commonly used as stop check valves. Refer to Figs. E and F.

Application Considerations

The force of gravity plays an important role in the functioning of a check valve and, therefore, the location and orientation of the check valve must always be given consideration. Lift and ball check valves must always be placed so that the direction of lift is vertical. Swing checks must be located to ensure that the disc will always be closed freely and positively by gravity.

The flow velocity of the fluid through the valve has a significant effect on the life of the check valve. The valve should be sized such that the fluid velocity under normal conditions is sufficient to keep the disc fully open and pressed against the stop. This minimizes disc fluttering, which is the primary cause of valve failure. Also, a check valve should not be located immediately downstream of a source of turbulence, such as a pump, elbow, control valve, or a tee-branch connection.

It is recommended that manufacturer’s recommendations be followed to provide the required straight run of pipe upstream of the check valve. Some manufacturers recommend 8-to-10 pipe-diameter length of straight run of pipe upstream of the valve. Sometimes, the layout and the space available may not allow compliance to manufacturer’s recommendations. Alternatives must be evaluated and the most reasonable and feasible approach be implemented.

A swing check valve may be used in the vertical run of a pipe only when the flow is upward. In addition, the flow velocity and the fluid pressure must be adequate to overcome the disc weight and swing it to the fully open position. In-line ball check valves are suitable for application in horizontal or vertical lines.

When the flow is suspected to be pulsating and low, use of a swing check valve is not recommended. Due to the continuous flapping of the swing disc against the seat, valves suffer considerable damage, and at times the swing discs can come loose.

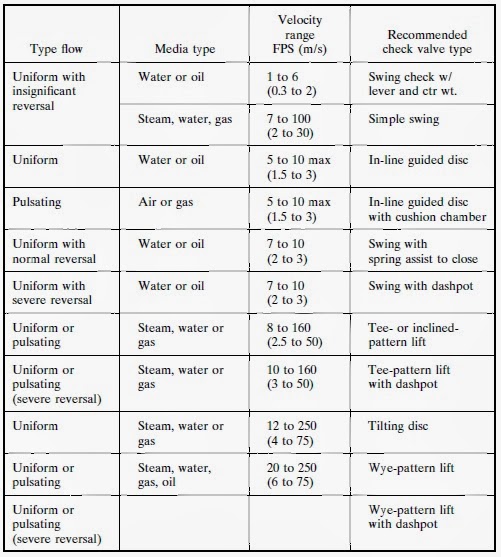

|

| Table 1: Application of Check Valves |

Table 1 summarizes preliminary application guidelines for selection of a suitable type of check valve. The user must evaluate specific application features to determine the right valve for the application.

Typical Applications of Check Valves

Table 1 provides a brief summary of different types of check valves and their typical applications. The preliminary guidelines of this table may be used to determine the suitable check valve for an application, considering the specifics of the application.

Download this article as PDF: Check Valves Types, Construction, Applications and Advantages

Tagged as :

PandID

Pipelines

Piping

Piping Design

Refinery

0 comments :

Post a Comment