The function of a bolt is to provide a clamp load or preload (Fp) to sufficiently compress and stress the gasket and resist the parting forces exerted by the hydrostatic end force and other external loads. The hydrostatic end force is created by the pressure of the internal fluid across the internal area of flange. The internal area is generally the inside diameter of the sealing element.

All bolts behave like a heavy spring. As you turn down the nut against the flange, the bolt stretches and the flange and gasket compress. All bolt-tightening methods result in stretching the bolt. The torque-tightening method uses the thread helix of turning the nut against the reactive forces of the flange to stretch the bolt. The hydraulic bolt-tensioning method utilizes an annular piston threaded on the end of the bolt to provide an axial stretch.

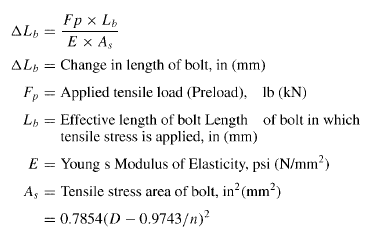

In its elastic region, bolts stretch according to Hooke’s law:

|

| Functions of Bolts in Piping Design |

where, D - Nominal diameter of bolt

n - is the number of threads per in

n - is the number of threads per in

Preload is the applied bolt load generated during tightening.

No comments:

Post a Comment