The flange-end connection defines the way in which it is attached to the pipe. The following are commonly available standard flange end types:

Weld-Neck (WN) Flange

Weld-neck flanges are distinguished from other types by their long, tapered hub and gentle transition to the region where the WN flange is butt-welded to the pipe. The long, tapered hub provides an important reinforcement of the flange, increasing its strength and resistance to dishing. WN flanges are typically used on arduous duties involving high pressures or hazardous fluids.

The butt-weld may be examined by radiography or ultrasonic inspection. Usually, the butt-welds are subject to visual, surface, or volumetric examinations, or a combination thereof, depending on the requirements of the code of construction for piping or a component. There is, therefore, a high degree of reliability in the integrity of the weld. A butt-weld also has good fatigue performance, and its presence does not induce high local stresses in the pipework.

Socket-Weld (SW) Flange

|

| Raised Face Socket Weld Flange |

Socket-weld flanges are often used on hazardous duties involving high pressure but are limited to a nominal pipe size NPS 2 (DN 50) and smaller. The pipe is fillet-welded to the hub of the SW flange. Radiography is not practical on the fillet weld; therefore correct fitting and welding is crucial. The fillet weld may be inspected by surface examination, magnetic particle (MP), or liquid penetrant (PT) examination methods.

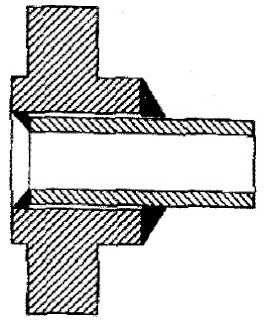

Slip-on Flanges

|

| Raised Face Slip-On Weld Flange |

Slip-on flanges are preferred to weld-neck flanges by many users because of their initial low cost and ease of installation. Their calculated strength under internal pressure is about two-thirds of that of weld-neck flanges. They are typically used on low-pressure, low-hazard services such as fire water, cooling water, and other services. The pipe is ‘‘double-welded’’ to both the hub and the bore of the flange, but, again, radiography is not practical. MP, PT, or visual examination is used to check the integrity of the weld. When specified, the slip-on flanges are used on pipe sizes greater than NPS 2¹⁄₂ (DN 65).

Composite Lap-Joint Flange

|

| Composite Lap Joint Flange |

This type of flanged joint is typically found on high alloy pipe work. It is composed of a hub, or ‘‘stub end,’’ welded to the pipe and a backing flange, or lapped flange, which is used to bolt the joint together. An alloy hub with a galvanized steel backing flange is cheaper than a complete alloy flange. The flange has a raised face, and sealing is achieved with a flat ring gasket.

Swivel-Ring Flange

|

| Swivel Ring Flange |

As with the composite lap-joint flange, a hub will be butt welded to the pipe. A swivel ring sits over the hub and allows the joint to be bolted together. Swivel-ring flanges are normally found on sub–sea services where the swivel ring facilitates flange alignment. The flange is then sealed using a ring-type joint (RTJ) metal gasket.

Blind Flange

|

| Blind Flange |

Blind flanges are used to blank off the ends of piping, valves, and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed of all the standard flanges. However, since the maximum stresses in a blind flange are bending

stresses at the center, they can be safely permitted to be stressed more than other types of flanges.

stresses at the center, they can be safely permitted to be stressed more than other types of flanges.

No comments:

Post a Comment