Rubber O-ring Bell and Spigot Joint

+Lined+cylinder+pipe+(LCP)+and+(b)+embedded+cylinder+pipe+(ECP)+profiles.jpg) |

| (a) Lined cylinder pipe (LCP) and (b) embedded cylinder pipe (ECP) profiles |

Figures A and B show a cross-section of the typical LCP and ECP bell and spigot joint. As can be seen, an O-ring rubber gasket is compressed into the spigot groove by the bell ring when assembled to form a water-tight seal. Portland cement grout is poured into a fabric band (diaper) by the installer to provide corrosion protection.

Restrained Joints

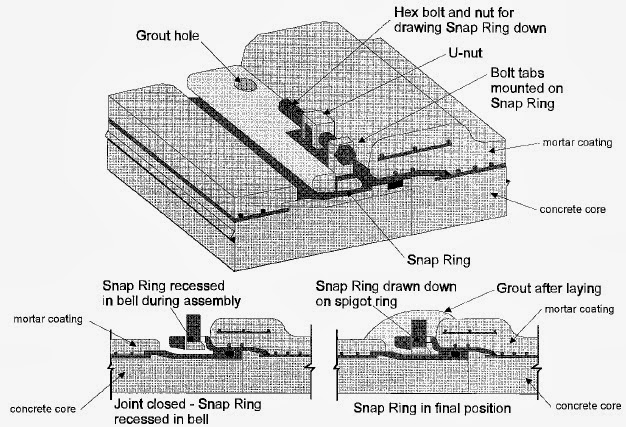

Figure C depicts a Snap Ring type restrained joint.

|

| Fig.C: Snap Ring restrained joint |

and

|

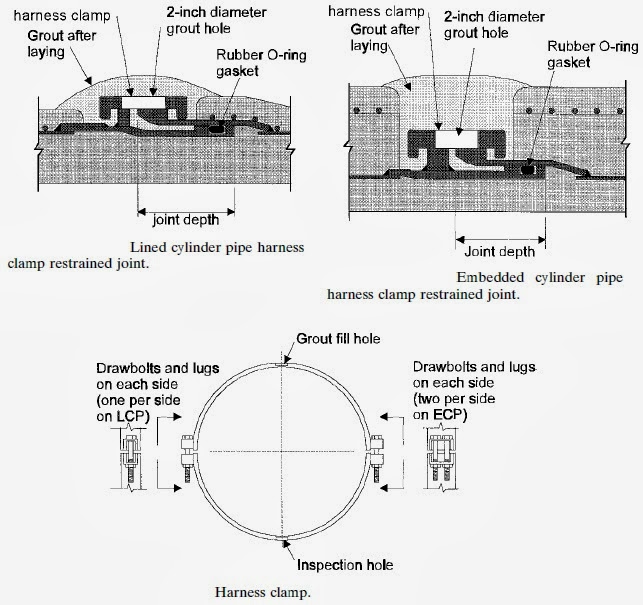

| Fig. D: Harness clamp |

Fig. D a harness clamp type restrained joint.

These joints can be used to resist axial tensile forces on the pipe due to unbalanced thrusts caused by internal pressure at fittings such as elbows, tees, and bulkheads. The Snap Ring joint incorporates a split ring which is pre-assembled in the manufacturing plant so that it is recessed into a groove in the bell ring. After the spigot is pushed home into the bell, the installer tightens a single bolt which draws the split ring down around the shank of the spigot ring.

This effectively locks the joint together. The harness clamp joint utilizes a two-part clamp which engages bars on the bell and spigot rings. After the spigot is pushed home into the bell, the installer places the clamp halves over the harness bars, securing them with bolts and nuts. The clamp installed in this manner locks the joint together.

Testable Joints

|

| Fig. E: Testable joint |

Figure E shows a joint configuration which allows for testing the joint seal without the need to fill the pipeline with water. These joints are normally used when pipe is installed in a manner that necessitates immediate verification of the gasket seal. This feature is sometimes necessary for certain pipelines in power, industrial, water, and wastewater plants; for pipe in tunnel casings; and for subaqueous pipelines. This can be an effective tool for finding a problem with a joint seal at the time it can most easily be corrected. Testable joints are normally available in diameters NPS 54 (DN 1350) and larger.

However, some manufacturers may be able to supply them in smaller diameters. Testable joints should not be considered a replacement for post-construction hydrostatic pressure tests since they do not confirm the overall system integrity (restrained joints or concrete thrust blocks) and water tightness of connecting appurtenances such as valves and access manholes.

Other types of special joints available for PCCP include subaqueous joints and bonded joints. Subaqueous joints, depicted in Fig. F, are designed to facilitate jointing underwater by divers. They normally incorporate external lug and drawbolt assemblies.

|

| Fig. F: Lined cylinder pipe & Embedded cylinder pipe |

|

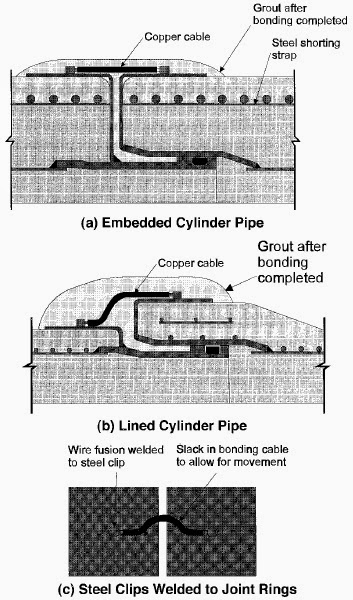

| Fig. G: Bonded joint - Exothermic fusion welded copper cable method |

Bonded joints, shown in Fig. G, are designed to provide electrical continuity across the joint for the future monitoring of electrical activity on the pipeline or for the application of cathodic protection.

No comments:

Post a Comment