Recently i got an email from "DecomWorld", an online Oil & Gas magazine related to oil & gas sector where those guys shared with me with few sets of presentations which i found highly useful and since i believe in formula of knowledge sharing with all, hence i took permission with them to share all of the presentations with you guys.

Wednesday, February 27, 2013

Download Set of Presentations related to Oil & Gas Sector

Posted by

Akki

on

1:04 PM

Be The First To Comment

Sunday, February 17, 2013

Concrete, Cement, and Cement-Lined Pipe

Posted by

Akki

on

1:13 AM

Be The First To Comment

Non-Reinforced Concrete Pipe

Nonreinforced concrete pipe for the conveyance of sewage, industrial waste, and storm water is made in sizes from NPS 4 to NPS 36 (DN 100 to DN 900). It is produced in accordance with ASTM Specification C14, Standard Specifications for Concrete Sewer Storm Drain and Culvert Pipe.

Nonreinforced-concrete drain tile is used for land drainage and for subsurface drainage of highways, railroads, airports, and buildings. It is made in sizes from NPS 4 through 36 (DN 100 through 900) in accordance with ASTM Specification C412, Standard Specification for Concrete Drain Tile, and AASHO M178, Standard Specification for Concrete Drain Tile. Drain tile is available in the standard quality, extra-quality, and special-quality classifications.

Sunday, February 10, 2013

Joining Ductile Or Cast-Iron Pipe - Part 1

Posted by

Akki

on

11:45 AM

Be The First To Comment

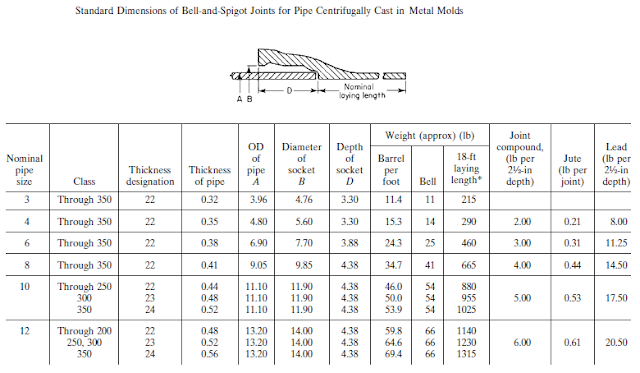

Bell-and-Spigot Joint

This joint for underground cast-iron pipe was developed as long ago as 1785. Standard dimensions are shown in Table below:

The joint may be made up with lead and oakum, sulfur compounds, or cement. Lead and oakum constitute the prevailing joint sealer for sanitary systems. Belland-spigot joints are usually reserved for sanitary sewer systems. These joints are not used in ductile iron pipe.

Sunday, February 3, 2013

Gaskets Materials, Compression and Relation to Bolting

Posted by

Akki

on

1:08 AM

Be The First To Comment

Since it is expensive to grind and lap joint faces to obtain fluid-tight joints, a gasket of some softer material is usually inserted between contact faces. Tightening the bolts causes the gasket material to flow into the minor machining imperfections, resulting in a fluid-tight seal. A considerable variety of gasket types are in common

use. Soft gaskets, such as cork, rubber, vegetable fiber, graphite, or asbestos, are usually plain with a relatively smooth surface. The semimetallic design combines metal and a soft material, the metal to withstand the pressure, temperature, and attack of the confined fluid and the soft material to impart resilience. Various

designs involving corrugations, strip-on-edge, metal jackets, etc., are available. In addition to the plain, solid, and flat-surface metal gaskets, various modified designs and cross-sectional shapes of the profile, corrugated, serrated, and other types are used. The object in general has been to retain the advantage of the metal gasket but to reduce the contact area to secure a seal without excessive bolting load. Effective gasket widths are given in various sections of the ASME Boiler and Pressure Vessel Code.

Subscribe to:

Posts

(

Atom

)